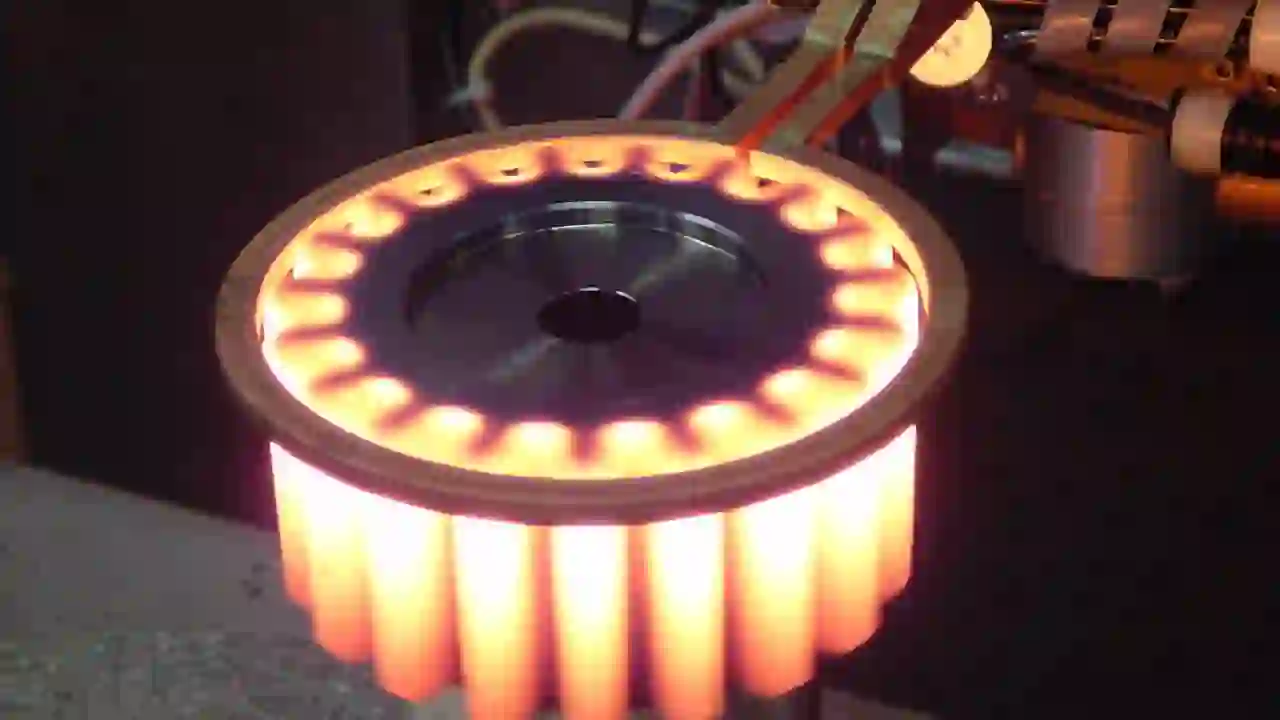

Induction hardening is the way toward hardening steel by heating it. An attractive rotating field finishes it to a temperature above or inside a particular change go. It is straight away, followed by extinguishing. This system of hardening can be explicitly applied to both fully just as surface hardening techniques. This is the sort of warm treatment process in which the metal part is warmed, and later, it is extinguished. The metal extinguished further experiences a martensitic change to upgrade the hardness and fragility of the particular region.

Head Techniques:

This hardening procedure can be performed predominantly by two strategies:

- Cross Hardening

- Single-shot Hardening

In the cross hardening frameworks, the workpiece to be taken a shot at is over and over went through the induction loop, and an extinguishing splash is being utilized. It is significantly used in creating some pole type segments, including directing parts, driving shafts and force device shafts, etc. The extinguish ring that is being used can also be a fundamental part. This technique is also material for the creation of edge parts, such as hacksaw edges, calfskin blades, paper blades, and lawnmower base sharp edges.

Necessities for Induction Hardening:

Undoubtedly, three things which are significantly required for this procedure to happen are as per the following:

- A high recurrence electrical force source

- A work loop to produce the attractive exchanging field

- Electrically conductive workpiece which is to be warmed

Before this warm treatment process is performed, it is essential to note the metal’s science, the modification of the metal’s temperature, and last yet not the least the metal attributes.

Tips for Successful Induction Hardening of Steels:

The determination of steel assumes a crucial job in this warm treatment process. For the most part, steel parts are solidified to get hold of some particular properties; for example, wear opposition, elastic, and exhaustion quality. Also, it should either be possible in a specific piece of the workpiece or throughout. The methodology includes heating the workpiece to a higher temperature than the austenitizing temperature. Afterward, the steel is permitted to cool at a rate that is sufficiently quick to change it to an utterly martensitic structure.

Effective Heat Treatment Method

In recent decades or something like that, there has been an inescapable innovative development in every segment. Despite the business new developments and one of a kind new gadgets have changed how we take a gander at things overall ventures and verticals, be it data innovation, wellbeing, or so far as that is concerned overwhelming metal. This development pattern has additionally brought another and important heating innovation called induction heating machine that is presently well known everywhere throughout the world. This innovation is utilized to solidify metal parts, and even though it’s anything but a troublesome procedure, some things must be remembered to lead the system effectively.

Chiefly, there are two ways to lead the induction hardening process, the cross hardening process, and the single-shot hardening process. In the cross hardening process, the metal item that must be heat-rewarded is gone through an induction loop a few times in an arrangement, while an extinguishing shower is at the same time used to layer the outside of the metal with a dissolvable fluid. This hardening procedure is utilized across ventures to produce an assortment of shaft-type metal articles like guiding segments, power device shafts, and driveshafts.

The single-shot hardening process also utilizes an induction loop. If, in this procedure, the metal item is embedded into the circle and kept still or pivoted for a prefixed period. In the business, this procedure is utilized to solidify little instruments, the edges of sophisticated formed apparatuses, and the level essences of devices like mallets. For the standard induction hardening machine strategy, a high recurrence power source and a working curl that creates substituting attractive fields are required to have the option to effectively direct warmth treatment on a work object that conducts power.

The procedure can be unpredictable. If you’re looking for a company that offers these types of assistance, make sure to utilize an organization that has a substantial permit, and uses the correct sort of gear for a reason.

Details news here https://todaybusinessinsider.com